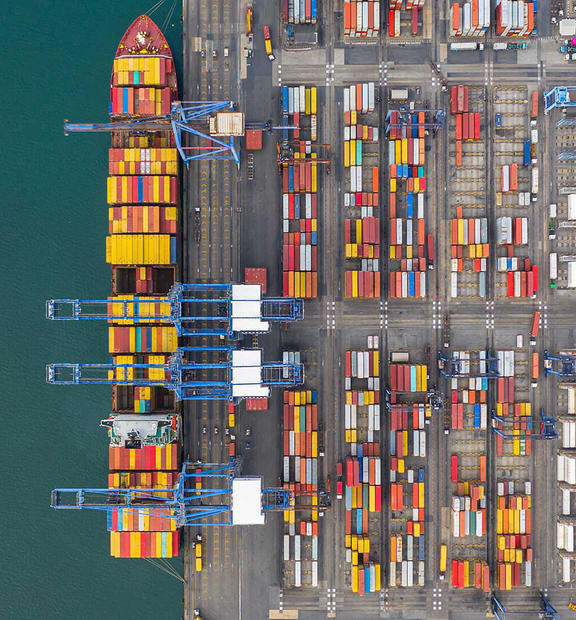

Wireless connectivity, cloud computing, sensor technology, big data analytics, machine learning and AI are all combining to enable the fourth Industrial Revolution – Industry 4.0 and the Industrial Internet of Things.

Industries have opportunities to innovate and change – adopting technology in new ways to automate, improve efficiency, do new things that weren’t previously possible and enable new business models.

Technology and Cellular IoT presents different opportunities to each industry and their supply chains and vendors. Success hinges on adoption of new technology, ideas and innovation – leading to new partnerships and collaboration between players in the ecosystem.

These IoT innovations represent trillions of dollars in new market opportunity for numerous industries. And it all relies on one critical thing – wireless connectivity.

Wireless Connectivity Challenges

The challenge is that wireless connectivity is not perfect. There are coverage gaps and there can be data performance variability. For human users, poor connectivity can lead to bad quality of experience and dissatisfied customers. For Industrial IoT applications, it can mean missing or delayed data, reduced application performance or applications stopping completely.

As applications become more widely used and relied upon, the costs and consequences of “getting it wrong” are increasingly high.

Most of us are familiar with the concept of cellular coverage and bars of service. If there are few or no bars, then wireless applications won’t work well or – with no coverage – at all.

What’s less understood and less predictable is what happens when lots of applications compete to use the network at the same time and place. The network gets overloaded and data performance is impacted – slower throughput means slower application responsiveness or, in applications like video, insufficient data causing the video to freeze.

Industrial IoT and automation involves a broad range of applications and use cases—ranging from massive sensor or meter deployments with occasional needs for connectivity to automation requiring uninterrupted high performance connectivity.

Different industries and applications therefore face different challenges and new approaches are necessary to address them. What is important is understanding what’s right for your industry and your application. Visibility into wireless connectivity is an important input to understanding wireless connectivity in the industrial IoT.

Understanding Wireless Connectivity in the Industrial IoT: Selecting the right connectivity provider

As industries move to automate and adopt IoT, one of the first choices is how best to achieve the required connectivity. Selecting the right technology and provider depends on multiple factors but the three most important are geography (operational coverage area), capability (required data performance) and volume (combination of data performance and cost).

Industries with large geographic coverage requirements typically find their needs best served by commercial cellular networks. Key actions or decisions are network selection and then price negotiations. To aid in network selection companies can use benchmarking and comparative testing for valuable data and insights into the coverage and data performance provided by each candidate network. This is best undertaken using on-board testing – measuring from the perspective of the intended application or business user and understanding wireless connectivity in the industrial IoT from the perspective of the T (thing requiring connectivity). For businesses like transit or deliveries with routes for example, networks can score quite differently.

For industries requiring coverage to specific locations or just their property or area of operation, private network deployment is becoming an increasingly viable option. Typically, this started as Wi-Fi as the IT department extended WAN connectivity through wireless, but, more recently, there is a trend towards deploying a private LTE or 5g cellular network. Cellular technology can offer improved performance and reliability together with the ability to better manage and control quality.

There are established processes and tools for operating and optimizing connectivity over cellular networks – and these can be applied to both private and public networks. In many cases, network operations and performance management are contracted out to either a cellular network operator or a network equipment vendor who have experience. Networks, however, are typically optimized for the “average” user – and only from the radio network perspective. Industrial IoT application requirements and mobility can be different to those of a cellular network user population making it important also to test service end-to-end from the application or “connectivity user” perspective.

Connectivity User vs Network Provider Perspective

Addressing IoT connectivity challenges requires a new focus on connectivity and application performance from the perspective of the connectivity user – enabling applications to function when and where needed.

This is different from the traditional connectivity provider or network centric focus of optimizing networks to deliver “average” quality of service to all users – and is achieved using on-board monitoring software clients and solutions.

There is help available

Thinking about connectivity from the end-user perspective is a paradigm shift for your business, but fortunately you can leverage the same technologies your wireless network has been using for years.

Read our whitepaper, “Industry 4.0 Connectivity Enabled Automation” for a roadmap to understanding wireless connectivity in the industrial IoT.